So, I wanted to share my little adventure from the other day with these valve balloons. You know the ones, usually foil, and they have that little tab or slit for inflation? Yeah, those. It sounds super basic, I know, blowing up a balloon, but sometimes the simplest things have their own little dance you gotta do.

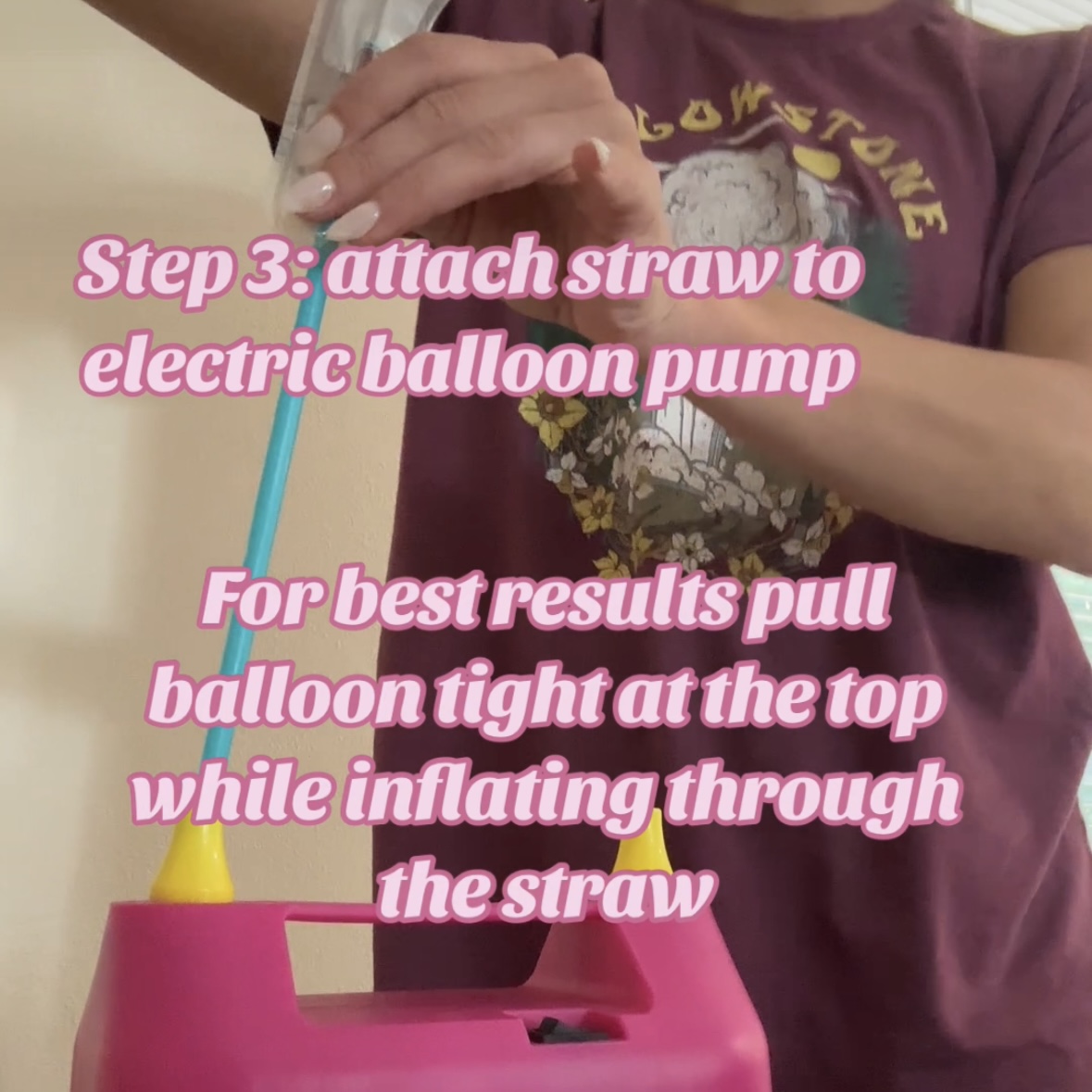

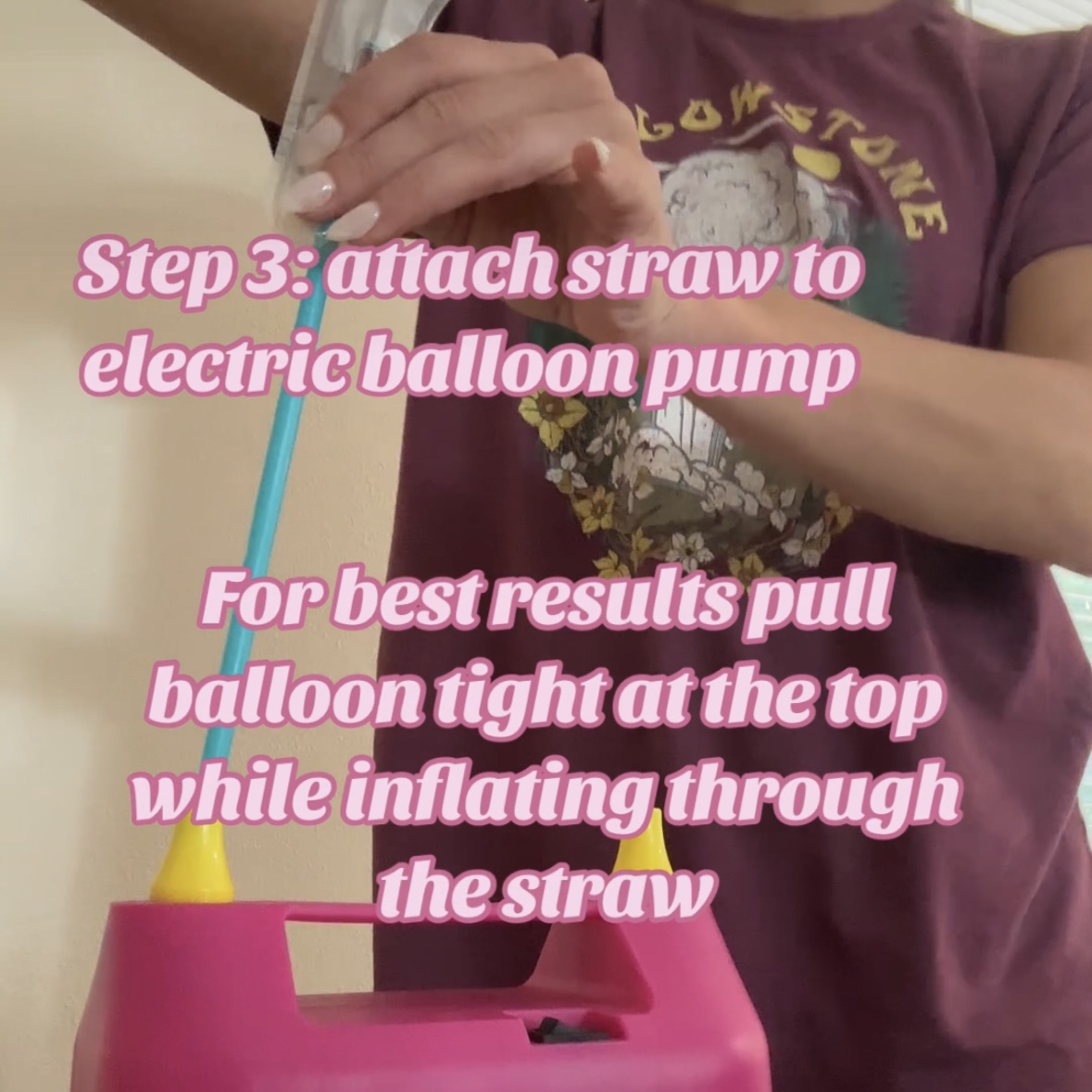

First off, I had this particular balloon, a shiny number for a small celebration we were having. It had been sitting in a drawer, and I figured, ‘time to bring this thing to life.’ So, I grabbed it. Then the hunt for a pump began. I knew I wasn’t going to try lung power on this one; these valve balloons are a bit stubborn for that, and you usually need a more precise way to get the air in. I remembered I had one of those small hand pumps, the kind that often comes with inflatable toys or something. Found it tucked away, thankfully with the right kind of narrow nozzle.

Now, the valve itself. This is where it sometimes gets a bit fiddly. I looked for the little marking, usually it says ‘VALVE’ or there’s an arrow. On this one, it was a bit hidden, just a little flap. I had to gently separate the layers of plastic at that flap. You gotta be careful here; I’ve heard of people accidentally poking a hole through the balloon itself if they’re too aggressive or use something sharp. I just used the pump nozzle itself, very gently, to sort of wiggle it in between the plastic sheets that make up the valve. It’s like threading a needle in slow motion sometimes.

Once I felt the nozzle slide in past the self-sealing part of the valve – it’s usually a couple of inches in – I started pumping. Slowly at first. I didn’t want to put too much pressure on it too quickly. I just kept a steady rhythm. You can see the balloon start to take shape, which is always the satisfying part. I continued pumping until it was firm but not rock hard. You don’t want to overinflate these foil types because they don’t stretch like rubber balloons; they just pop. Learned that the hard way a long time ago with a different one. Quite a bang, that was.

When it looked good and full, I stopped pumping. Then, I carefully slid the pump nozzle out. The great thing about these valve balloons is that they are typically self-sealing. As soon as you pull the nozzle out, the valve is designed to press shut and keep the air in. No frantic tying of knots while air hisses out. I just pressed down on the valve area a little bit, just to make sure it was flat and sealed tight.

And there it was, all puffed up and ready. It’s not rocket science, obviously, but it’s a process. Each type of balloon has its own little personality, I guess. These valve ones are pretty neat for how long they hold air once you get them inflated properly. Way better than the old latex ones that are looking sad by the next morning. So yeah, that was my valve balloon inflating session. Done and dusted.