Okay, so everyone’s always yapping on about helium for welding, right? Like it’s some kind of wonder gas that’ll fix all your problems. I heard it all – hotter arc, deeper penetration, especially for stuff like thick aluminum. Sounded pretty good on paper, I gotta admit.

My First Go With Helium

So, I had this one project. A real beast of a job, trying to stick together some chunky aluminum parts. Argon just wasn’t cutting it, or maybe I just wasn’t good enough with it, who knows. Anyway, I figured, “Alright, let’s give this fancy helium a shot.”

Getting the tank wasn’t too bad, but man, the price tag. Way more than my usual argon. First red flag, but I was committed, or maybe just stubborn.

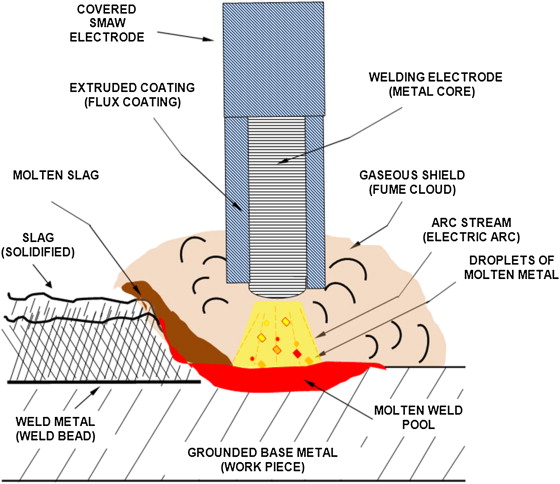

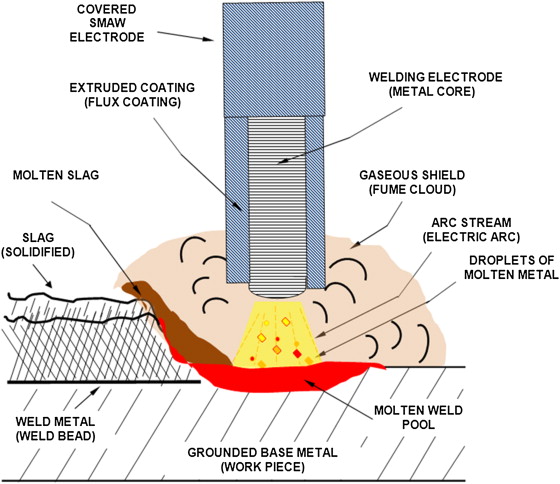

I hooked it up to my TIG welder, same old machine. Here’s what I noticed pretty quick:

- The arc definitely felt different. Hissier, I guess? And yeah, it seemed hotter.

- Penetration was better, no doubt. It bit into that thick aluminum much more aggressively than argon alone.

- Controlling the puddle, though? That was another story. It was way more fluid, almost squirrelly. Took some real getting used to.

I burned through a fair bit of rod and scrap trying to get the hang of it. My welds weren’t instantly perfect, that’s for sure. It’s not like you just switch gases and suddenly you’re a welding god.

Now, Why Was I Even Bothering?

You might be wondering why I went to all this trouble for one job. Well, it’s a bit of a story. I’d been working on this custom frame for an old bike I was restoring. It wasn’t for a client or anything, just for me. But I’m a perfectionist, sometimes to a fault. This one particular joint, a thick aluminum bracket to the main frame, was giving me nightmares. I’d tried welding it a couple of times with just argon, and it looked okay on the surface, but I just wasn’t confident about the penetration. I kept imagining it cracking on the first big bump.

I remember complaining about it to an old timer I know, a guy who’s seen it all in the fabrication world. He just grunted and said, “Ever try helium mix?” He didn’t elaborate much, just that. Classic him. So, that little comment stuck in my head. It wasn’t like he was selling it as a miracle cure, more like a “well, there’s this other thing you could try if you’re desperate” kind of suggestion.

So, there I was, spending extra on helium, re-learning puddle control, all for this one bike frame that probably nobody but me would ever scrutinize that closely. It felt a bit ridiculous, honestly. I almost gave up a couple of times and just thought about bolting the darn thing together instead.

But I pushed through. Eventually, I got a weld I was happy with. It definitely looked like it had bitten in deep. The bike’s still holding up, by the way.

So, What’s the Real Deal with Helium?

Look, helium isn’t a magic wand. It does have its uses, especially for thick aluminum or other non-ferrous metals where you need that extra heat and penetration. But it comes with its own set of challenges:

- Cost: It’s pricier than argon. No getting around that.

- Control: The puddle can be harder to manage, especially if you’re used to argon.

- Availability: Might not be as easy to get as argon depending on where you are.

For me, it’s a tool for specific situations. I don’t use it every day. Most of the time, good old argon does the job just fine if your technique and machine are dialed in. I’m not rushing out to replace all my argon tanks with helium, that’s for sure. It’s more like that one special wrench you only pull out a few times a year, but when you need it, you’re glad you have it, even if it was a bit of a pain to get and learn to use.

So yeah, that’s my experience. No fancy theories, just what happened when I tried it out in my own shop. Maybe it helps someone else cut through the hype a bit.